Fasteners for Thin Sheet Metal

Self-clinch nut

Self-Clinching Nuts provide strong reusable female threads in panels that are too thin to be conventionally tapped.

Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst providing a flush finish on the underside of the panel

Like all self clinching fasteners they are installed using a parallel squeezing force so require access to both sides of the panel.

Clinch Nuts are available in various thread sizes, manufactured from electro zinc plated steel, 300 and 400 series stainless steel, and aluminium and are suitable for installation in ductile steel and aluminium panels with a recommended maximum hardness of 80 HRB for steel parts, 70 HRB for 300 series stainless steel parts, 90 HRB for 400 series stainless steel parts and 50 HRB for aluminium parts

Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst providing a flush finish on the underside of the panel

Like all self clinching fasteners they are installed using a parallel squeezing force so require access to both sides of the panel.

Clinch Nuts are available in various thread sizes, manufactured from electro zinc plated steel, 300 and 400 series stainless steel, and aluminium and are suitable for installation in ductile steel and aluminium panels with a recommended maximum hardness of 80 HRB for steel parts, 70 HRB for 300 series stainless steel parts, 90 HRB for 400 series stainless steel parts and 50 HRB for aluminium parts

Material & Finish

- Electro Zinc Plated Carbon Steel (ZI) parts are suitable for installation in ductile panels with a maximum recommended hardness of 80 HRB

- 300 Series Stainless Steel (A2) part are suitable for installation in ductile panels with a maximum recommended hardness of 70 HRB.

- 400 Series Stainless Steel (400) parts are suitable for installation in ductile panels with a maximum recommended hardness of 90 HRB.

- Aluminium (AL) parts are suitable for installation in ductile panels with a maximum recommended hardness of 50 HRB.

Part Number Examples

Part number is made up as follows:

- (Type)-(Thread code)-(Material code)-(Material/Finish code)

For example:

- NS-M3-0-ZI (Clinch Nut-M3-0.8mm min sheet thickness-electro zinc plated carbon steel)

- NS-M4-2-A2 (Clinch Nut-M4-1.4mm min sheet thickness-stainless steel)

- NS-M5-1-AL (Clinch Nut-M5-1.0mm min sheet thickness-aluminium)

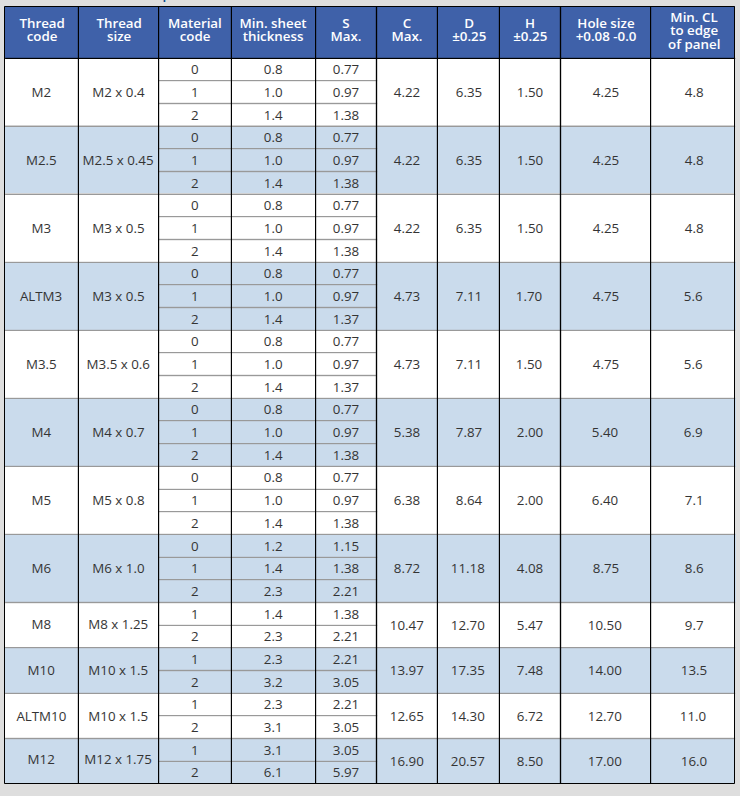

Steel and Stainless Steel part dimensional

"NOT JUST FASTENERS BUT FASTENING SOLUTIONS"

As a team of engineers, we pride ourselves in helping our customers solve difficult application problems.

Social Media

Pages

- Home

- About Us

- Industries

- Products

- Brand

- Resources

- Contact Us

Brands

- Bralo

- Tubtara

- J Lanfranco

- Auto-sert

- LCM

- Allfa

- Others

CONTACT US

KAPASI Inc.,

KAPASI FASTENERS.,

No.83, 1st main road,

New Binny Layout,(opp. Balekai Mandi),

Tank bund road,

Bangalore-560023, India

- +91-80-26745566, 26740233,

- 9845010997

- pkapasi@kapasiinc.com